| You are here: Home » Customer Imagery |

Click here to return to the main index page.

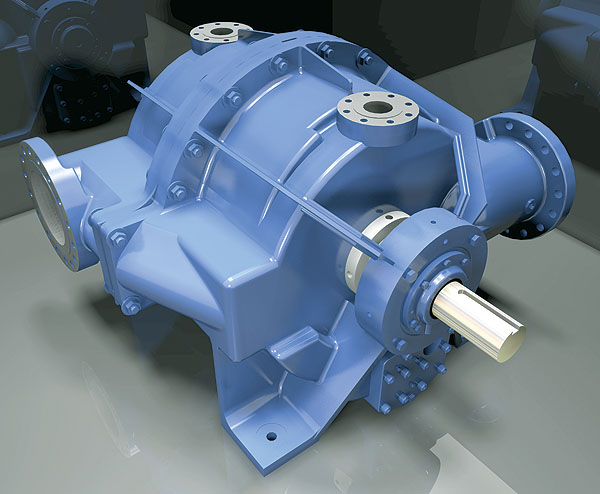

The HP-9 is a high pressure, single stage, twin lobe liquid ring compressor, designed to handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and vinyl chlorine monomer recovery.

The model was created in Autodesk Inventor by the Gardner Denver Nash engineering department. The Inventor data was imported into Okino's NuGraf software by Ed Steinerts who used it to optimize the CAD data, compose the 3D scene, add materials and textures, then create the final high resolution renderings.

Copyrights: Images used by permission and Copyright (c) by Ed Steinerts and Gardner Denver Nash.

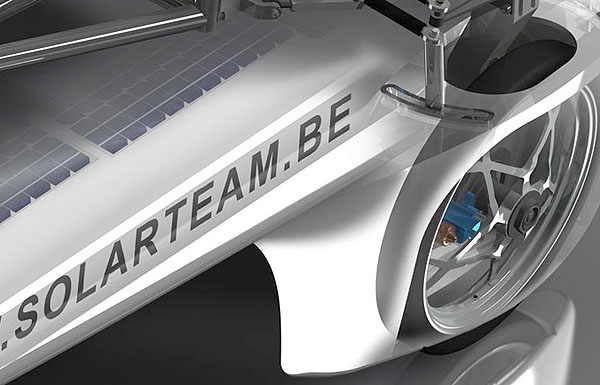

Ludwig Desmet is a design visualization expert at Renderhouse, Belgium. Renderhouse specializes in technical illustrations, product presentations and animations. As quoted from Ludwig, "PolyTrans is a great help in transferring the multiple file formats to Cinema-4D that we use as our main rendering application."Renderhouse was the official 3D media sponsor for the "Solarteam". These technical renderings were created for the press presentation brochure, and showed the ins and outs of all the vehicle components.

The solar powered vehicle was created in Catia V5 and transferred to Okino PolyTrans software where it was optimized and re-exported for use by Cinema-4D. The source files were 77MB and the final scene 2.6 million polygons. The solar panel texture map is 10kx3k pixels, designed in Photoshop. The final image was rendered with Cinema-4D, Advanced Render Module.

The solar powered vehicle finished 2nd place in the Panasonic World Solar Challenge. The Belgian Umicore Solar Team II, a group of 14 student engineers, designed and build the car in about 16 months.

Car specs: Prepreg Carbon composite body 29kg. High graded Aluminium tubular frame 19kg. Csiro engine in rear wheel, Efficiency 97%, regenerative braking. High density Lithium Polymer battery pack Germanium Space Graded solar cells. Total weight approx 175 kg. Max speed over 140 km/h

Copyrights: Images used by permission and Copyright (c) by Solarteam and Ludwig Desmet, Renderhouse BVBA.

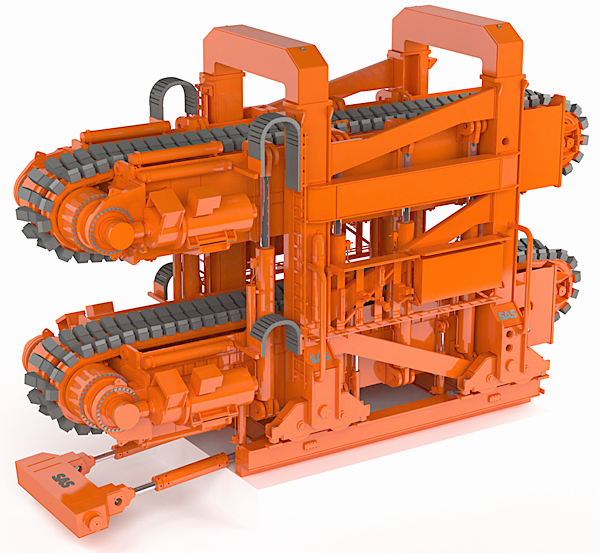

This is another in the series of CAD visualizations created by Ludwig Desmet at Renderhouse, Belgium (see other images above). The client was SAS Gouda of the Netherlands, a manufacturer of maritime cable laying equipment. The pipe tensioner machine was created in ProE/Creo then imported into Okino's PolyTrans|CAD for heavy optimization, prior to sending the data to Cinema-4D for final rendering. The final dataset consisted of a 5.83 million polygon scene.Copyrights: Images used by permission and Copyright (c) by Renderhouse BVBA. and SAS Gouda (Netherlands).

INDUSTRIAL PDD is an industrial design consultancy company located in Stuttgart, Germany. They deliver customized product design and development solutions that encompass workshops, design ideas, design detailing, design modelling, prototyping, design CAD data, tooling CAD data and support of series production.

The image is of the "CP3 Scooter", designed entirely in SolidWorks, then converted + optimized by Okino PolyTrans software into Maxon's Cinema-4D program. The result was an award winning design that has become famous for INDUSTRIAL PDD.

Copyrights: Images used by permission and Copyright (c) by Christoph Bodensieck, Industrial PDD & Switch Mobility.

Click here to view 10 short animations in MPEG format (12MB total) created by Pieter Suur for this Eaton Electric B.V. project.

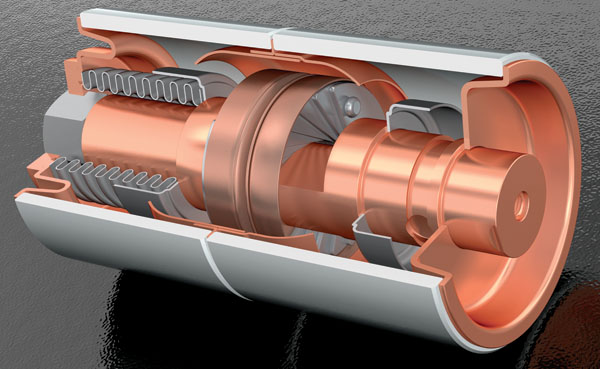

The first image is of a 'Vacuum Interrupter' (circuit breaker) visualization made for Eaton Electric B.V. The model was composed of approximately 120,000 polygons, 75% of the data from 'One Space Designer'. The IGES CAD data was transported into Maya using Okino's PolyTrans-for-Maya.

The second image is of a 'Xiria Ring Main Unit' (low and medium voltage switchgear) visualization made for Eaton Electric B.V. The model was composed of 400,000 polygons, 50% data from FormZ and 50% from 'One Space Designer'. The data was transported cleanly into Maya using PolyTrans-for-Maya for mesh fixing, smoothing and data translation. The image was rendered with Mental Ray for Maya.

As quoted by Pieter Suur, "As a technical 3D-illustrator and animator I often work with different applications and found out that Okino's converters made it easy to exchange data between them. Eaton Holec needed visualisation of their Xiria Ring Main Unit for marketing purposes. At that time parts of the installation were drawn in 'One Space Designer' and the engineering was not finished yet. We had to find a reliable way to reimport changed parts of the installation into my system. Other parts I already made in FormZ on the Mac and Rhino. Because I also wanted to make animations with the Xiria unit, all the data had to come together in Maya. Okino's PolyTrans-for-Maya + CAD converters were the solution for effortless translation of all this data into Maya. Spending less time for converting the data meant that I could pay more attention to the final image."

Copyrights: Images used by permission and Copyright (c) by Pieter Suur, Suur Graphics and Eaton Electric B.V.

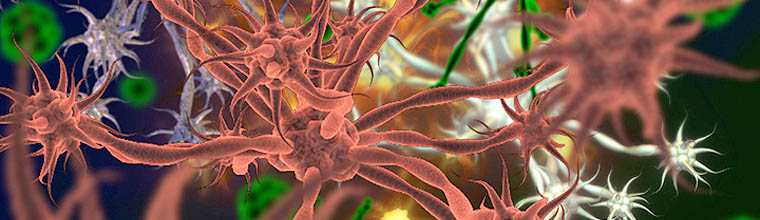

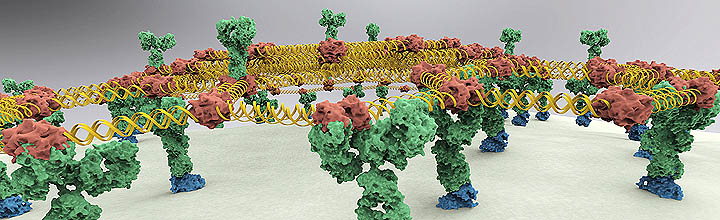

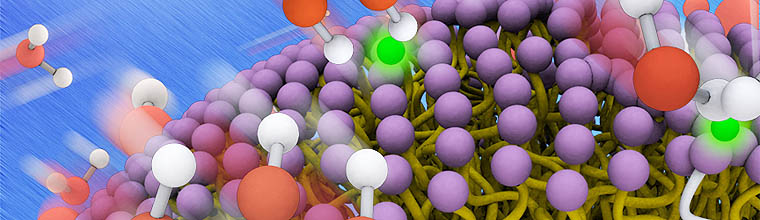

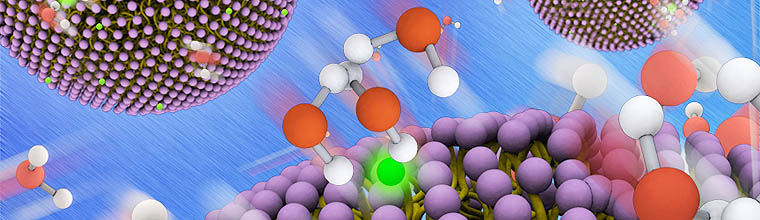

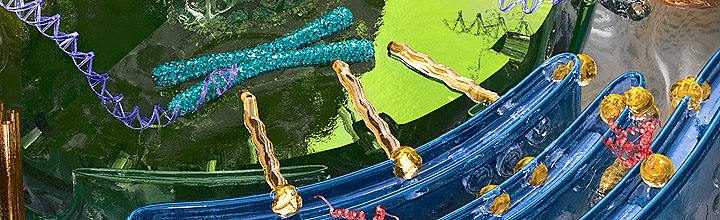

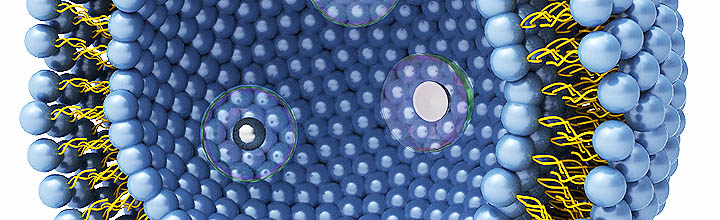

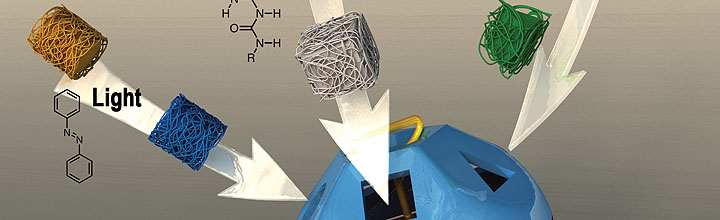

Peter Allen has been the marketing and creative content director for UCSB College of Engineering (UC Santa Barbara) for the last 3 decades. Peter is a prolific visualization artist, using Autodesk's Maya to bring together various forms of visualization data for acccurate and dazzling rendering + animation. For over a decade Peter has been a core user of Okino's PolyTrans-for-Maya 3D conversion software. It allows Peter to import and assemble 3D assets from various external 3D packages, CAD sources, visualization sources and molecular file formats into Maya.

Click on any image shown below to see its full scale rendition. Please also refer to the 52 select images found in the Peter Allen customer case study.

All graphics are Copyright by UCSB Engineering and Peter Allen, All Rights Reserved. No images may be reproduced without the explicit permission from UCSB Engineering and Peter Allen, permission which Okino Computer Graphics has received.

These are CAD renderings of Kemppi welding machines, visualized in Newtek Lightwave by Keith Mann of Spikey Animation. Kemppi is a world-leading manufacturer of arc welding equipment and a provider of solutions for highly productive welding, with 530 employees.

Keith Mann received the 3D MCAD models of the Kemppi equipment in STEP and Parasolid formats then used Okino's PolyTrans|CAD conversion system to process the BREP solids into a crack-free and efficient model for rendering in Lightwave. All renderings were made using Lightwave's radiosity lighting solution. Each scene consisted of 500k to 1 mil polygons.

As quoted by Keith Mann, "The Kemppi UK sales and marketing director contacted me needing a welding machine Character for a promotional animation. That turned into a nice 10 minute promotional piece for a welding show. The potential of animation and CGI was well received by Kemppi but the re-modelling of their data by hand for Lightwave was seen as a stumbling block. Hence, we purchased Okino's software to do a proper conversion of the original Kemppi CAD into Lightwave, allowing me to focus primarily on the visual aspect of my customer work and not on the rebuilding of the source CAD data. PolyTrans|CAD is perfect for me, as it allows a simple transfer at various levels of detail. As a result of this efficiency in my production pipeline, I have come to produce images and animations for Kemppi over the years, usually for exhibitions, sales conferences, marketing etc. Kemppi is unique in that that they are the only client that comes straight to me rather than through a production company."

Copyrights: Images used by permission and Copyright (c) by Spikey Animation and Kemppi Oy.

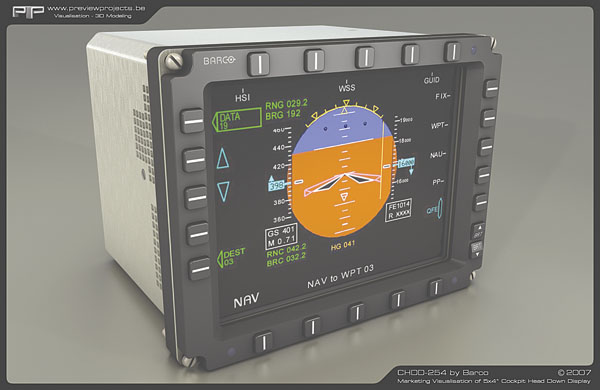

Bert Moors, visualization expert and mechanical engineer at Barco Avionics Displays, used Okino PolyTrans to convert and optimize his complex ProE/Creo assemblies into Maxon's Cinema-4D for final product visualization and animation.

The image is of a Barco 'Cockpit Head-Down Display' that will be used for both civil and military applications.

As quoted from Bert Moors, "I must say that we are very pleased with the way Okino's PolyTrans imports complete and highly complex ProE/Creo Assemblies into Maxon's Cinema-4D. Compared to earlier, where we had to make STL or STEP exports of all separate parts and then had to reassemble them inside the rendering application, PolyTrans in combination with Cinema-4D has given us a huge gain in time spent on renders. Truly a very valuable tool"

Copyrights: Images used by permission and Copyright (c) by Bert Moors, Barco Avionics and Preview Projects.

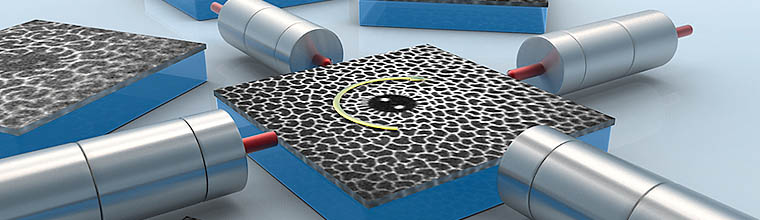

Brian Harp specializes in 3D animation, visual effects and motion graphics for Digital Engine Studios, Inc.

As quoted by Brian, "Working closely with our client we were faced with the challenge of converting a new multi-million dollar lithography unit into 3ds Max for animation and rendering. The problem: The unit was designed in ProE/Creo Our solution: Okino PolyTrans with the native ProE/Creo importer - after hours of research on the web, this was the best choice. Not only was this our software of choice but, the customer support was second to none. If I had questions, Robert Lansdale of Okino was there quickly with the answers. The customer support was incredible.

The lithography unit consisted of 2783 internal and external parts and 8,344,991 faces. Because of confidentiality reasons we took our computer in to their office and converted all the files during lunch. The process was fast and reliable. We then animated and rendered our animations in 3ds Max using a 3rd party plugin for global illumination. The surfacing and conversion of the models turned out exactly what we expected and our client was extremely pleased with the quality and realism of their new lithography unit product launch. With many of our clients being in the hi-tech industry we'll definitely be using PolyTrans more often."

Copyrights: Images used by permission and Copyright (c) by Brian Harp and Digital Engine Studios, Inc.

As quoted by Boris Rabin, "We purchased PolyTrans and used it for 3D data conversion and optimization of datasets created for the NASA MER space program (Mars Exploration Rover Mission). It is fantastic software. My colleagues at another NASA center spent days using three software packages on what took me 15 minutes using PolyTrans alone (polygon reduction in batch mode worked like a charm)."

Copyrights: Images used by permission and Copyright (c) by Boris Rabin (Development Lead), NASA/Ames Research Center, FutureFlight Central.

Astro Lighting, of Harlow UK, is a longer term user of Okino's PolyTrans-for-Maya software, which is utilized to directly convert and optimize SolidWorks CAD data into Maya. Final rendering is done via ART's ArtVPS rendering hardware. Okino has been associated with ART and their customers, directly and indirectly, since the mid-90's. The image is of a Misumi IP44 Spotlight, used as part of the Astro Lighting product catalog.

Copyrights: Images used by permission and Copyright (c) by Stuart Wells and Astro Lighting Ltd.

This is one of the more famous images associated with Okino software and many of our print media advertisements. It was designed by Daka Designs Ltd. (Hong Kong) in SolidWorks, then transferred natively into Maya using PolyTrans-for-Maya for final lighting, scene composition and rendering.

Copyrights: Images used by permission and Copyright (c) by Daka Designs Ltd. Hong Kong.

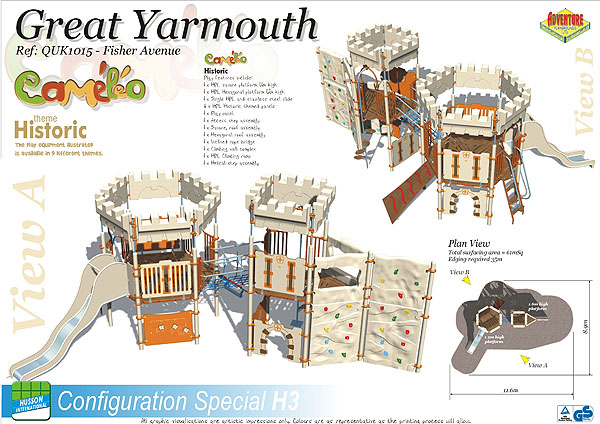

The Husson International group was founded in 1960 and is now a leading European manufacturer of play and sports equipment. Husson UK used Okino PolyTrans as the mechanism to convert their ProE/Creo datasets of the children playground equipment into AutoCAD DXF/DWG files. Those were then imported into AutoCAD and rendered to the images shown below. The final layouts were assembled in Corel.

As stated by Husson, "The images are of the Cameleo range of equipment from Husson. The main selling point of this equipment is that it is available in 9 different themes. The particular themes below are of the 'Rustic' theme. The equipment is modular and can therefore be supplied in small configurations as shown or in much larger assemblies."

See more images in the Husson customer case study.

Copyrights: Images used by permission and Copyright (c) Husson UK.

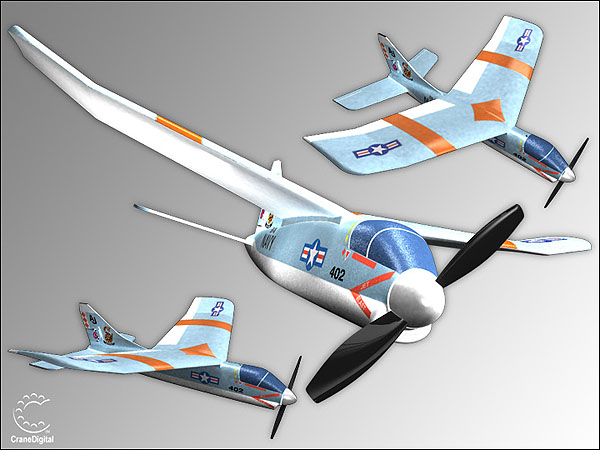

CraneDigital, run by John B. Crane, is a 3D illustration and animation studio in Fort Collins, Colorado. John specializes in 3D scientific/technical illustration and animation. His work has to be seen to be believed -- it is truly awe inspiring. His work has been featured in Okino print advertisements for many years.

As stated by John, "Because my education and training are in art I approach the discipline of engineering as the 'fine art' it deserves to be portrayed as. I've had the good fortune to learn many 3D workstation applications and have settled on LightWave and 3ds Max.

I've used PolyTrans|CAD for countless projects, moving seamlessly between 3ds Max and LightWave. PolyTrans handles ProE/Creo files extremely well, as evidenced by the project shown for Waterpik. Why move between applications? Sometimes it's as simple as a slightly different look a client is after. Sometimes it's more complicated, like creating a motion, object or affect more easily in one application than another. Sometimes a client will already have Max files and want that to be the starting point. With PolyTrans, moving between different worlds is a reliable, "promisable" task. Without it my life would be far more difficult."

Copyrights: Images used by permission and Copyright (c) by John B. Crane and CraneDigital.

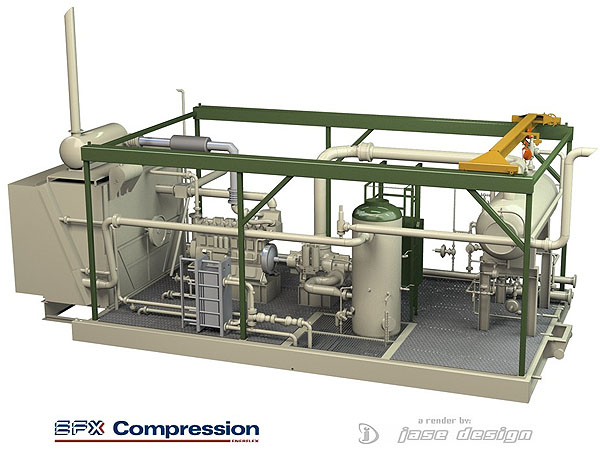

Jason Clark is a senior mechanical designer, as well as a freelancer in engineering product visualization rendering and technical illustration.

Jason's exposure to rendering applications and CAD has lead him to deal with file conversions and large geometry, and thus often gets intrigued in dealing with highly detailed models. His current pipeline of applications includes Okino PolyTrans, Cinema-4D, Modo, and ProE/Creo.

The first image of a chopper motorcycle was a promotional piece done for PMC Tech. to commemorate the Wildfire release of ProE/Creo. The data was converted from native ProE/Creo files using Okino's "Granite" CAD technology and moved into Cinema-4D for final rendering. The model contained 3.75 million polygons.

The second image is of a mechanical compressor unit, converted from original AutoCAD models. The image was rendered in Cinema-4D.

Copyrights: Images used by permission and Copyright (c) by Jason Clark, Jase Design, Inc.

The first image is a visualization of a 19th century building in SOHO, New York City. It was created in trueSpace and 3ds Max, then combined and converted directly into Newtek's Lightwave via Okino's PolyTrans.

The second image is an interior visualization made for the Newmark global real estate management company. The data mostly came from AutoCAD via DXF files where they were imported into PolyTrans and then re-exported to Lightscape for final radiosity rendering.

As quoted from Arnold Gallardo (visual content creator), "Most jobs that I do come from different sources, from CAD/CAM data, Illustrator files, to DWF/DXF as well as from several 3D applications. In my workflow I use whatever application works best for solving a particular problem, so there is a huge necessity for having seamless 3D file translation/conversion and PolyTrans has served me well. I used to export from the 3D application itself and import that data back into another application but it is almost impossible to get a perfect conversion because of some file format's inherent structure like using 'instancing', proprietary UV mapping modes etc. My experience with Okino's technical support has been wonderful when dealing with problems during production work."

The SOHO building scene contains 700k polygons, 46 textures, 11 lights and 5 cameras.

Copyrights: Images used by permission and Copyright (c) by Gallardo Associates and Newmark.

The first image is a product visualization of "George", an iPod docking music system. The engineering was done with SolidWorks. Okino's SolidWorks conversion system and dedicated PolyTrans-for-Maya CAD connector was used to set up an idealized scene for Maya to render using Mentalray. The final TV commercial animation can be viewed online here.

The second image is a product visualization of a "Proficient Audio Systems M6" audio controller. Surfacing techniques, combined with HDRI based lighting and subtle depth of field brought this image from a simply surfaced CAD model to one of amazing clarity and realism.

Copyrights: Images used by permission and Copyright (c) by Nino Del Padre.

As quoted from Carl Andrew Johnson, "I specialize in developing industrial animations and was provided with a large data set of 400 CAD files to convert into LightWave. The Okino NuGraf software was able to batch convert all the files over night. Using the polygon reduction tools in NuGraf I was able to bring the resulting polygon count down to a manageable 3 million polygons. Robert Lansdale of Okino has been a great help by modifying the LightWave export plug-in giving me great output flexibility."

Copyrights: Images used by permission and Copyright (c) by Carl Johnson and Bechtel National Inc.

As quoted from Bob Burgun, "This poster image was made for a special event held at Rolls-Royce Corporation in Indianapolis regarding the 'Joint Strike Fighter' program.

The image was created using a F-35B model purchased from TurbSquid and transferred over to Lightwave for rendering via Okino's native PolyTrans-for-3dsMax software. There were nine versions of the model created using different textures with flags from each of the countries involved in the Joint Strike Fighter program. The textures were created using Photoshop CS2, CorelDraw and Adobe Illustrator CS2.

The nine separate models were rendered using Lightwave. Each model contains 1,065,222 polygons. All of the rendered images and the vapor trails were composited using Photoshop by Keith Marshall. The final image was printed on HP DesignJet 130 large format printer for display during the Joint Strike Fighter event."

Copyrights: Images used by permission and Copyright (c) by Bob Burgun and Rolls-Royce Corp.

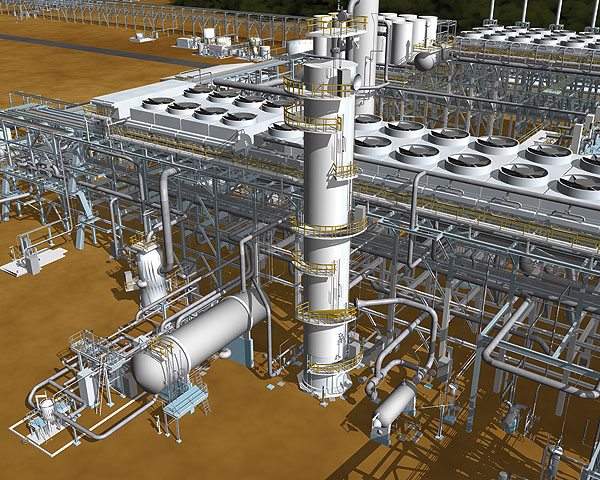

As quoted by Vic Cherubini, President, EPIC Software Group, "We have been using PolyTrans-for-3ds-Max for well over a decade now. Two days before Christmas a large engineering contracted us to animate an absolutely gargantuan oil refinery modeled in AutoCAD and Navisworks We could not open it, far less convert it and do animation without the computer crashing. We contacted Okino's CTO, Robert Lansdale, who analyzed and worked on it for 2 days, returning it to us on Christmas eve as a fully optimized 3ds Max scene that we could manipulate in real time, and instructions on how to repeat the process ourselves! And at what cost? None, other than to upgrade to the newest software release. Needless to say Okino now has a customer for life. While their software is great, their customer service is unbelievable!"

See more images in the EPIC Software customer case study.

Copyrights: Images used by permission and Copyright (c) by EPIC Software and CB&I.

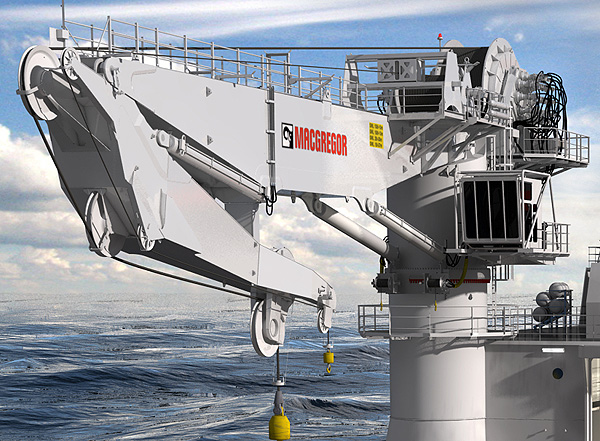

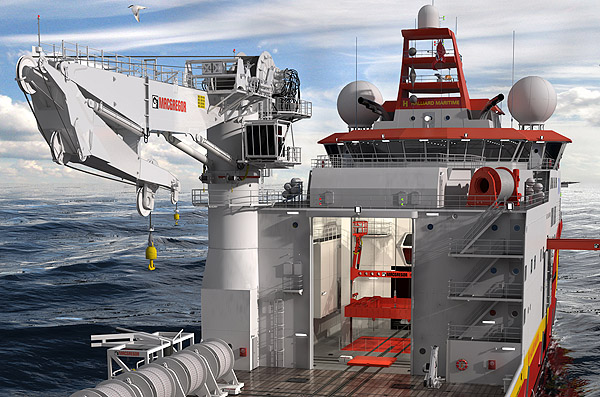

Cargotec Corp is a EUR 2.6 billion company that focuses on the efficiency improvement of cargo flows on land and sea.

Scott Garriott is a lead training developer at Cargotec (MacGregor offshore equipment subsidiary). He receives engineering models from other departments in ProE/Creo, Autodesk Inventor, SolidWorks, IGES, STEP and SAT file formats. The data is reformatted, converted and optimized for efficient rendering in 3ds Max using Okino's PolyTrans|CAD+DCC conversion system and PolyTrans-for-3dsMax.

The imagery is of a mock-up IMR-Con vessel (subsea Intervention, Maintenance & Repair + Construction) of a design made by Scott, equipped with numerous advanced MacGregor load-handling systems (the products which Cargotec designs, builds and sells). Numerous CAD file formats were imported into the final 3d model. The polygon count in 3ds Max was 6.52 million.

The ship design includes an advanced module handling system with moonpool, 2 ROV handling systems (called LARS - one overside, and one via a moonpool), a deck skid system, Ultra-Deep Lifting System, heave compensated offshore crane, large rescue boat davit and various deck winches.

Copyrights: Images used by permission and Copyright (c) by Scott Garriott and Cargotec Corp - MacGregor offshore equipment.

This complex and massive Pluto gas platform 3D model came from Microtation and was transformed, optimized and imported directly into Maya using Okino's PolyTrans-for-Maya software. The final animation was shown on Australian TV.

As quoted from Steve Nichols, "The Media Jungle was commissioned by McDermott Industries Australia to produce an animation outlining the installation of the Pluto Jacket. The animation is used in induction courses for the teams deployed to complete the installation activities and provides a useful training and safety guide. The Pluto project is one of Woodside Energies largest undertakings with the Jacket installation contract alone worth over AUS$100 million.

The model was imported from a series of Microstation design files through to Okino's PolyTrans software, totaling 82mb. The full model had a polygon count in excess of 20 million but PolyTrans reduced this to 4 million with no significant reduction of detail. The 15 minute sequence took over 125 hours to render using a Dual Processor, Quad Core DELL Workstation."

Copyrights: Images used by permission and Copyright (c) by Steve Nichols and Woodside Energy Ltd.

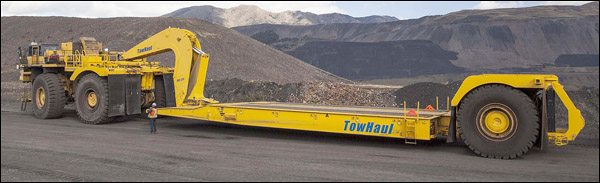

Photorealistic rendering of CAD data has come a long way ever since Okino introduced CAD converions to LightWave users more than 25 years ago. Mark Clevidence has been working for TowHaul Corp. for 14 years and manages the IT & Cutshop departments; he works with their graphic artists to produce videos and photos for tradeshows and marketing materials. His tool of choice has been Newtek's LightWave software for over 15 years. Mark used Okino's PolyTrans|CAD product to transform his SolidWorks models of the TowHaul truck components and trailer over to highly optimized native LightWave files for immediate rendering & animation. The final scene consisted of 8.48 million polygons (5.6 million in the trailer alone), composited over a photograph of a real mining site (using LightWave's 'shadow catcher' node).

TowHaul Corp. designs and manufactures custom trailers, tow trucks, sand spreaders, water tanks and dragline bucket transporters for the mining industry. They have 230+ units running in 24 countries around the world. They make 'lowboys' that carry 120 tons to 1600 tons with the one in the image below going to Canada for 315 ton mining hauls.

Copyrights: Image used by permission and Copyright (c) by Mark Clevidence & TowHaul Corp.

For comparison, the following is a real photograph of the TowHaul 'lowboy' in action.

Design firm 'Nose AG' of Switzerland has been an active user of Okino's PolyTrans|CAD product for well over 15 years. Their teams have used the software to transform a plethora of different CAD files formats (but mainly SolidWorks) into Cinema-4D for concept vbisualizations.

Nose Design has developed into one of the largest and most renowned Swiss design agencies. They help domestic and international companies and brands to develop clever, innovative products and services that successfully and sustainably assert themselves on the market. Versatility, technical competence, experience and passion make Nose an ideal partner for innovation and design, from creation to marketable implementation.

Copyrights: Image used by permission and Copyright (c) by NOSE AG Design Intelligence